Astro PFP FR Graphite

![]() High Pressure Sealant

High Pressure Sealant

Download any of the following data sheets:

KEY: CE Marked Documents

CoC's are Certificate of Constancy of Performance

TDS's are Technical Data Sheet

ETA European Technical Assessment Sheet

UKTA UK Technical Assessment Sheet

Product Features

- Classified in most constructions for plastic pipes, cables and combustible pipe insulations.

- Easy to apply.

- High sound insulation.

- Low emissions - environmentally and user friendly.

- Simple to apply with a smooth surface finish.

- Permanently flexible – will accommodate movement up to 12.5%.

- No priming necessary for application to most materials; see the installation instructions for further details.

- Suitable for most surfaces, included concrete, bricks, Leca, steel, wood, gypsum, glass, plastics and most non-porous surfaces.

- Hardens quickly, tack free after 1 hour.

- The fire performance specification of the joint filler has been derived when the joint filler has been allowed to cure for 30 days.

- Minimum 12 months storage time.

- 30 years working life.

Description

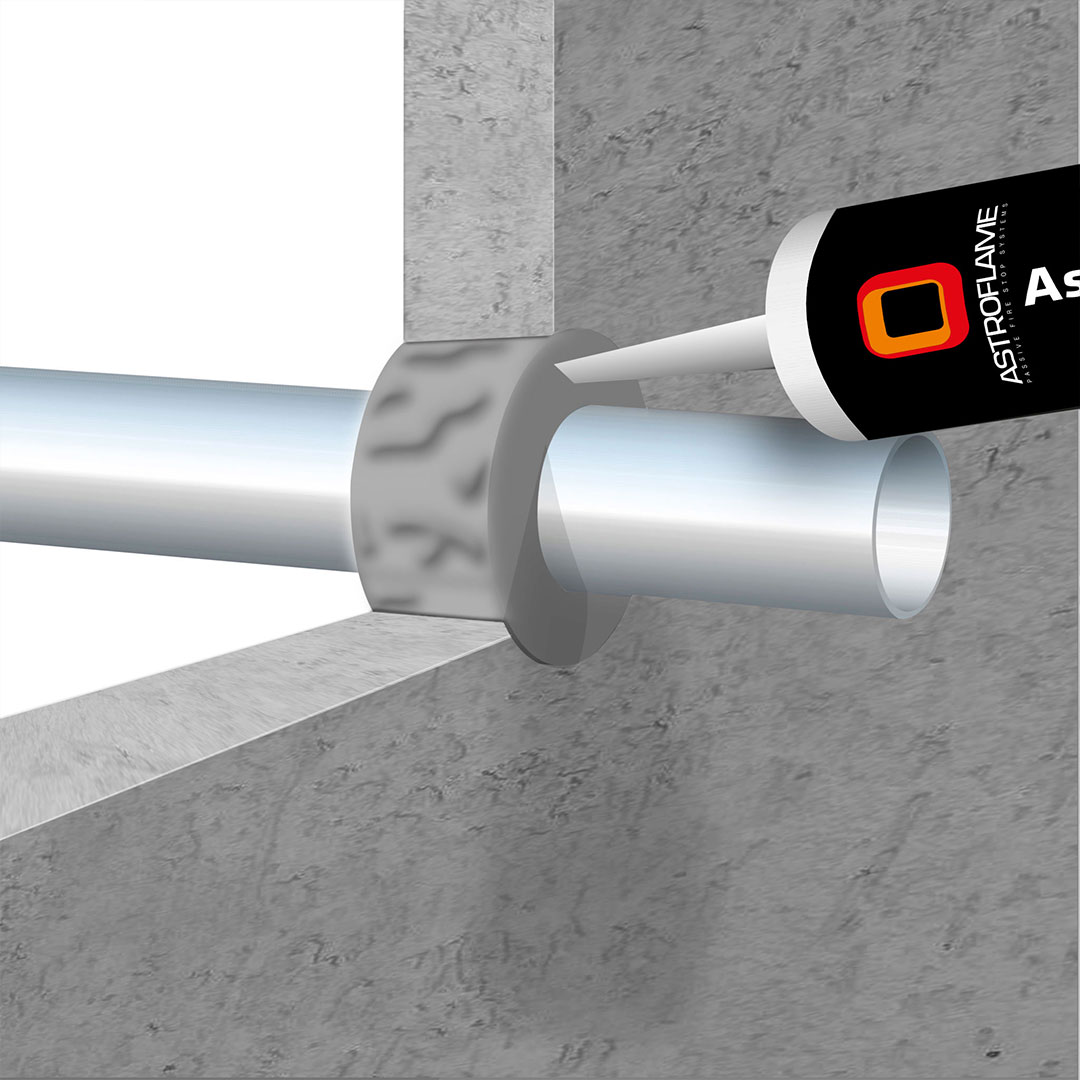

Astro PFP FR Graphite is a high specification formulation designed to prevent the spread of fire, smoke and gases through openings in fire rated walls and floors. Astro PFP FR Graphite expands when it is subjected to fire and closes openings around penetrations when any combustible or low temperature melting materials have burnt away.

Astro PFP FR Graphite is designed to fire seal difficult services which traditional fire rated mastics do not achieve such as large plastic pipes.

Astro PFP FR Graphite can be used with a suitable filling material, i.e. stone wool or Astroflame Backing material in order to ensure correct width to depth ratio and to reduce the shrinking of the sealant during curing. Minimum depth and maximum width of the joints are included in the installation instructions. Thermal activation takes place at 150 °C when the material will expand (intumesce) to prevent the passage of fire and smoke for periods up to 4 hours.

Sound Insulation

| Description | Sound reduction |

| Single sided seal ≥ 25mm depth | Rw 53 dB |

| Double sided seal ≥ 25mm depth | Rw > 53 dB |

Astro PFP FR Graphite has been tested at EXOVA BM Trada (UKAS accredited); according to EN ISO 10140-2:2010. Usage of any backing material is optional, due to the tests being conducted with sealant only.

Emission data (indoor air quality)

| Compound | Emission rate after 3 days | Emission rate after 4 weeks |

| TVOC | 51 μg/m3 | 20 μg/m3 |

| TSVOC | ᐸ 5 μg/m3 | ᐸ 5 μg/m3 |

| VOC w/o NIK | ᐸ 5 μg/m3 | ᐸ 5 μg/m3 |

| R Value | 0.17 | 0.14 |

| Formaldehyde | ᐸ 3 μg/m3 | ᐸ 3 μg/m3 |

| Acetaldehyde | ᐸ 3 μg/m3 | ᐸ 3 μg/m3 |

| Carcinogenic | ᐸ 1 μg/m3 | ᐸ 1 μg/m3 |

| n.d. or ᐸ means not detected | ||

| Regulation or Protocol | Conclusion |

| French VOC Regulation | A+ |

| French CMR components | Pass |

| Italian CAM | Pass |

| ABG / AgBB to the guidelines of DIBt | Pass |

| Belgian Regulation | Pass |

| EMICODE | EC 1 PLUS |

| Indoor Air Comfort GOLD ® | Pass |

| Blue Angel (DE-UZ 123) | Pass |

| BREEAM-International | Exemplary Level |

| BREEAM-NOR | Pass |

| LEED v4.1 | Compliant |

Astro PFP FR Graphite has been tested by Eurofins Product Testing; reports available upon request.

Pipe end configurations

When testing pipes, one can choose not to cap (or close) the pipe, or cap the pipe inside the furnace, or outside the furnace, or on both sides. The configuration chosen depends on the intended application of the pipe and/or the installation environment. The code defining if a pipe is capped is stated after the fire classification. For instance EI 60 C/U which means the pipe was capped inside the furnace, and uncapped outside the furnace. The test configuration defines the approvals possible.

Our engineering judgment based on EN 1366-3:2009 are:

| Intended use of pipe | Pipe end condition4) | |

| Rainwater pipe, plastic | At drainage | U/U1) |

| Not at drainage | C/C2) | |

| Drainage or sewage pipe, plastic | Ventilated drain | U/U1) |

| Unventilated drain | U/C1) | |

| Drain w/water trap | U/C1) | |

| Not at drainage | C/C2) | |

| Pipe in closed circuit (water, gas, air, electricity etc.) | C/C2) 3) | |

| Flue gas recovery system pipe, plastic | U/C1) | |

| Pipe with open ends and ≥ 50cm length on both sides, plastic | U/U2) | |

| Pipe supported by suspension system, metal | Fire rated support | C/U1) |

| Non-fire rated | U/C1) | |

| Waste disposal shaft pipe, metal | U/C1) | |

1) Suggested in EN 1366-3:2009. 2) Astroflames's judgment based on tests. 3) Metal pipes should have fire rated support. 4) U/U classified fire seals cover C/U, U/C and C/C. C/U classified fire seals cover U/C and C/C. U/C classified fire seals cover C/C.

Air Permeability

| Positive Pressure (Pa) | Leakage (m3/h) | Negative Pressure (Pa) | Leakage (m3/h) |

| 25 | 0.00 | 25 | 0.00 |

| 50 | 0.00 | 50 | 0.00 |

| 100 | 0.00 | 100 | 0.00 |

| 200 | 0.00 | 200 | 0.00 |

| 300 | 0.00 | 300 | 0.02 |

| 450 | 0.03 | 450 | 0.06 |

| 600 | 0.13 | 600 | 0.12 |

Astro PFP FR Graphite has been tested at Warringtonfire Testing and Certification Ltd (UKAS accredited); according to EN 1026: 2016.

Technical Data

| Condition | Ready for use, water based graphite sealant |

| Specific gravity | 1.56 - 1.60 |

| pH | 8.00 – 9.50 |

| Reaction to fire | B - s1, d0 |

| Flash point | None |

| Expansion in fire | Approx. 1 : 25 |

| Non-sticky | 60 minutes |

| Film forming | 30 minutes |

| Totally hardened | 3 to 5 days depending on thickness and temperature, full cure may take up to 30 days |

| Flexibility | Low to medium 12.5% according to ISO 11600 |

| Durability | Class Z2 intended for internal conditions with humidity classes other than Z1, excluding temperatures below 0°C |

| Thermal conduct | 0.85 W/mK (+/- 3%) @ 20mm depth |

| Storage | 12 months stored in unopened cartridges. To be stored in temperatures between 5°C and 30°C |

| Working life | 30 years |

| Service temp. | -15 to +75°C |

| Application temp. | +4 to +30°C |

| Compatibility | Suitable for use with most materials, but should not be used In direct contact with bituminous materials |

| Limitations | Should not be used in permanently damp areas or in joints with excessive movement, joints at floor level or joints below the ground |

| Classification | CE-marked - Sealant for fire rated penetrations class EI 240 |

| Standard colours | Dark grey (may grow darker during curing) |

Product Availability

| Product Code | Description | Colour | Size |

| AFPFPGRAPH | Astro PFP FR Graphite - Cartridges | Dark grey | 310 ml |

Installation

We have technical representatives who provide assistance in the selection and specification of the products on this site and should be consulted for exact installation and product suitability. Ensure an early engagement with ourselves, designers, main contractor and specialist installers before any installation. Other trades and/or manufacturers may need to be consulted. For in-depth information, specification and technical advice please call our Head Office on:

Telephone: +44 (0)1329 844 500 Email: sales@astroflame.com

Maintenance

All interested parties, designer, specifier, main contractor and specialist installers should provide access to allow the fire stopping seals to be regularly inspected and maintained, as well as records kept of such maintenance at minimum periods of 12 months, as required by the Regulatory Reform Order, and repaired if necessary. Reference should be made to ASFP TGD 17 – Code of Practice for the Installation and Inspection of Fire Stopping.

Competency

It is vital that those entrusted to design or install a fire stopping product have the necessary levels of competence to undertake the task professionally and thoroughly. The level of competency required will be commensurate with the expected complexity of the building. All designers must eliminate, reduce or control foreseeable risks that may arise during installation, construction or maintenance when preparing or modifying designs. Clients should ensure that the principal designer and principal contractor carry out their duties under CDM regulations. The ASFP foundation course in passive fire protection provides essential knowledge as part of demonstrating competency and understanding in this key fire protection specialism.

Additional Notes

Please refer to the ETA/UKCA sheet for fields of application for this product. For further information on installation requirements please refer to the manufacturer of the services and the wall/floor specification to ensure the compatibility of this product, if in doubt please contact the technical team with services and wall/floor specification on:

Telephone: +44 (0)1329 844 500 Email: sales@astroflame.com

Health and Safety

The product does not present any known health hazards during or after installation. Normal good industrial and personal hygiene practices should be observed. For further information on health and safety requirements please contact the technical team on:

Telephone: +44 (0)1329 844 500 Email: sales@astroflame.com

Web Page