Download any of the following data sheets:

KEY: CE Marked Documents

CoC's are Certificate of Constancy of Performance

TDS's are Technical Data Sheet

ETA's are European Technical Assessment Sheet

UL Documentation are UL - EU Certificate

UKTA UK Technical Assessment Sheet

Product Features

- CE & UKCA Marked.

- ULEU Accreditation.

- Fire resistance tested in flexible walls, rigid walls and floors.

- Tested in Linear Joints up to 50mm wide.

- Tested in large service openings up to 490 x 150mm.

- Tested with Metallic Pipes, Cables, Cable Bunches, Cable Trays and Cable Ladders, please refer to the test certification.

- For use in low movement joints, remains flexible.

- Shelf Life 18 months.

- Tested in accordance with EN1366-3:2009 - Fire Resistance - Penetration Seals.

- Tested in accordance with EN1366-4:2009 - Fire Resistance - Linear Seals.

- Classified in accordance with EN13501-2 - Fire Resistance.

- Tested in accordance with EN10140-2:2010 - Airborne Sound.

- Tested in accordance with EN1026:2000 - Air Permeability.

Description

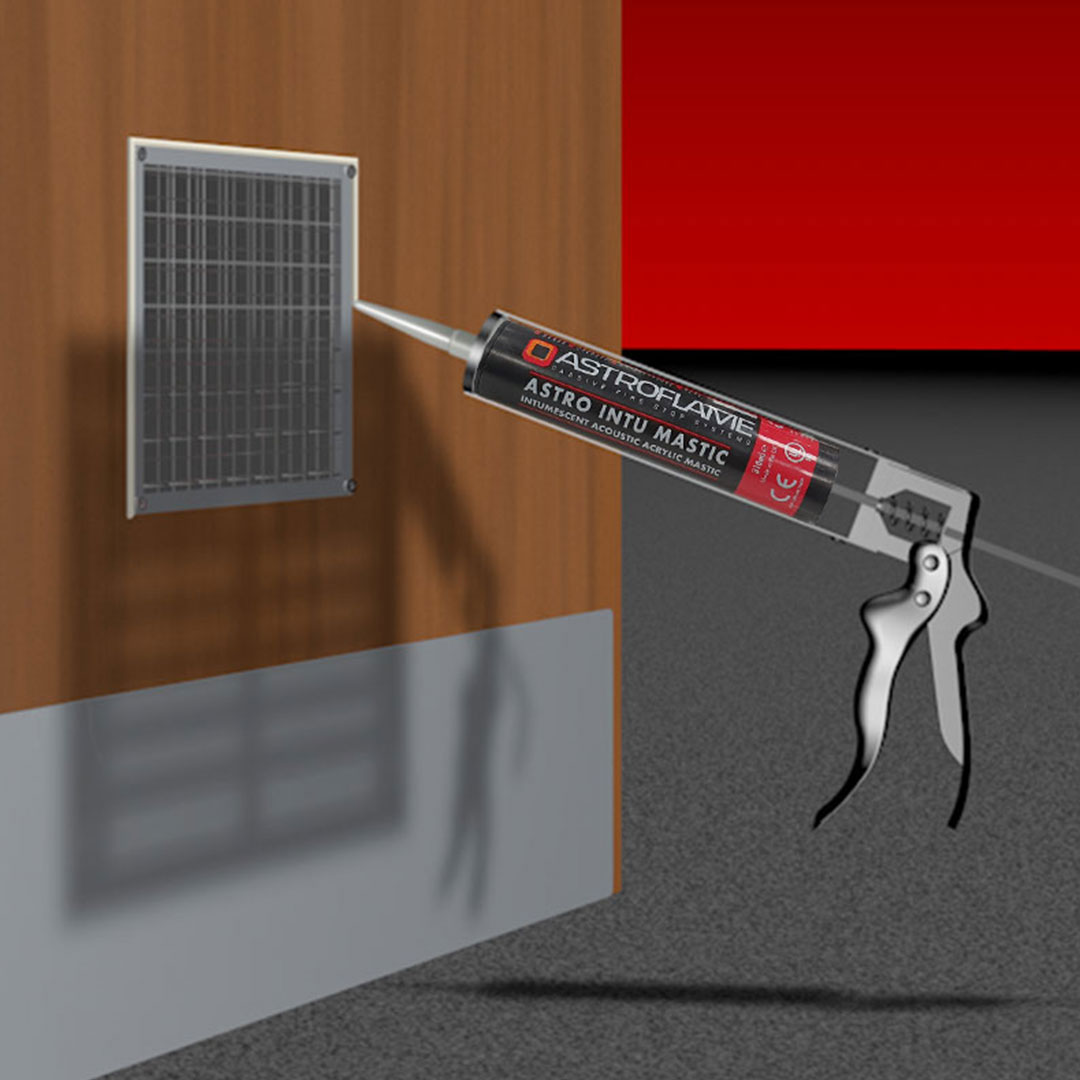

Astro Intu Mastic is a water based acrylic sealant used to reinstate the fire resistance of wall and floor constructions in linear joints and where apertures are penetrated by multiple services. Astro Intu Mastic Fire Resistant Sealant has been developed utilising specialist polymer technologies allowing it to be tested and Certified to internationally recognised standards, including CE, UKCA marking and UL Listings. Astro Intu Mastic Fire Resistant has been tested and Certified as part the Astroflame Fire Stopping range. The Astro Intu Mastic system can be installed across a variety services and substrates including,

- Flexible and Rigid Walls

- Rigid Floors

- Multi-Service penetrations

- Blank Openings

- Head of Walls

- Astro Batt

Properties

| General Characteristics | Inspection Method | Value |

| Product Data (uncured) | ||

| Density (S.G) | ASTM D792:13 | 1.63 |

| Appearance | Paste, matt finish | |

| Resistance to flow | ISO 7390 : 2003 | Pass |

| Handling & Storage For unopened material, store in a well ventilated, dry, cool environment. Recommended temp ranges +5°C - +35°C. Protect against exposure to direct sunlight. Always ensure that safe manual handling procedures are followed at all times. For information and advice on the safe handling, storage and disposal of chemical products, please refer to the most recent Safety Data Sheet (SDS) click here |

||

| Product Data (after curing) | ||

| Hardness Shore A | ISO 7619-1 : 2010 | 63/39 |

| Movement Capability | 7.5% | |

| Operating Temperature °C | -5 to 40 | |

| Loss Mass of Mass on Heating | ISO 3451-1 (Method A) | 68.34 |

| Flexibility - Bend Test | ISO 1519 | Pass |

| Conditioning | EOTA TR024 | Type X |

| Handling & Storage For unopened material, store in a well ventilated, dry, cool environment. Recommended temp ranges +5°C - +35°C. Protect against exposure to direct sunlight. Always ensure that safe manual handling procedures are followed at all times. For information and advice on the safe handling, storage and disposal of chemical products, please refer to the most recent Safety Data Sheet (SDS) click here |

||

Product Availability

The Astro intu Mastic Comes in Three Colours - White , Brown & Grey in Both 310ml Cartridge & 600ml Foils

| Product Code | Description | Size |

| AFIM | Astro Intu Mastic White | 310ml |

| AFIMB | Astro Intu Mastic Brown | 310ml |

| AFIMG | Astro Intu Mastic Grey | 310ml |

| AFIMWFOIL | Astro Intu Mastic White - Foil | 600ml |

600ml Foils in a Brown or Grey colour available P.O.A

Installation

We have technical representatives who provide assistance in the selection and specification of the products on this site and should be consulted for exact installation and product suitability. Ensure an early engagement with ourselves, designers, main contractor and specialist installers before any installation. Other trades and/or manufacturers may need to be consulted. For in-depth information, specification and technical advice please call our Head Office on:

Telephone: +44 (0)1329 844 500 Email: sales@astroflame.com

Maintenance

All interested parties, designer, specifier, main contractor and specialist installers should provide access to allow the fire stopping seals to be regularly inspected and maintained, as well as records kept of such maintenance at minimum periods of 12 months, as required by the Regulatory Reform Order, and repaired if necessary. Reference should be made to ASFP TGD 17 – Code of Practice for the Installation and Inspection of Fire Stopping.

Competency

It is vital that those entrusted to design or install a fire stopping product have the necessary levels of competence to undertake the task professionally and thoroughly. The level of competency required will be commensurate with the expected complexity of the building. All designers must eliminate, reduce or control foreseeable risks that may arise during installation, construction or maintenance when preparing or modifying designs. Clients should ensure that the principal designer and principal contractor carry out their duties under CDM regulations. The ASFP foundation course in passive fire protection provides essential knowledge as part of demonstrating competency and understanding in this key fire protection specialism.

Additional Notes

Please refer to the ETA/UKCA/UL-EU sheet for fields of application for this product. For further information on installation requirements please refer to the manufacturer of the services and the wall/floor specification to ensure the compatibility of this product, if in doubt please contact the technical team with services and wall/floor specification on:

Telephone: +44 (0)1329 844 500 Email: sales@astroflame.com

Health and Safety

The product does not present any known health hazards during or after installation. Normal good industrial and personal hygiene practices should be observed. For further information on health and safety requirements please contact the technical team on:

Telephone: +44 (0)1329 844 500 Email: sales@astroflame.com

Web Page